Two Step Cross Docking in SAP Warehouse Management

Two Step Cross Docking in SAP Warehouse Management

Introduction :** **

What is Cross Docking

It’s a process in which Inbound deliveries or Inbound Transfer requirements is mapped with outbound deliveries or outbound Transfer requirements. This way any finished goods received in Warehouse from production plant can be loaded directly in outbound trailer for customer delivery without any inbound material handling.

This saves a lot of labor & time from converting inbound delivery to inbound Transfer Order followed by doing put away and then picking from storage Bin and bringing material to good issue staging area for Sales Order.It also help in reduction of warehouse storage space.

Material types like perishable or pre packed materials or which don’t need quality checks are well suited for cross docking decisions.

Types of Cross Docking

1: Planned Cross Docking: In this process, users makes cross docking decisions before arrival of finished product in WM.

2: Opportunistic Cross Docking: In this process, decision is made post arrival of goods in warehouse.

Cross Docking Execution Types** **

1: One step Cross Docking: In one step cross docking goods are transferred from Good Receipt area to Goods Issue area.

2: Two Step Cross Docking Execution : In two step cross docking goods are first moved from Good Receipt Zone to a temporary storage type (cross docking area) and then goods are transferred from this storage type to goods Issue area. Please note opportunistic CD is always executed in one step.

In this document, we will discuss steps for two step cross docking.

Configuration for Two step Cross Docking Scenario

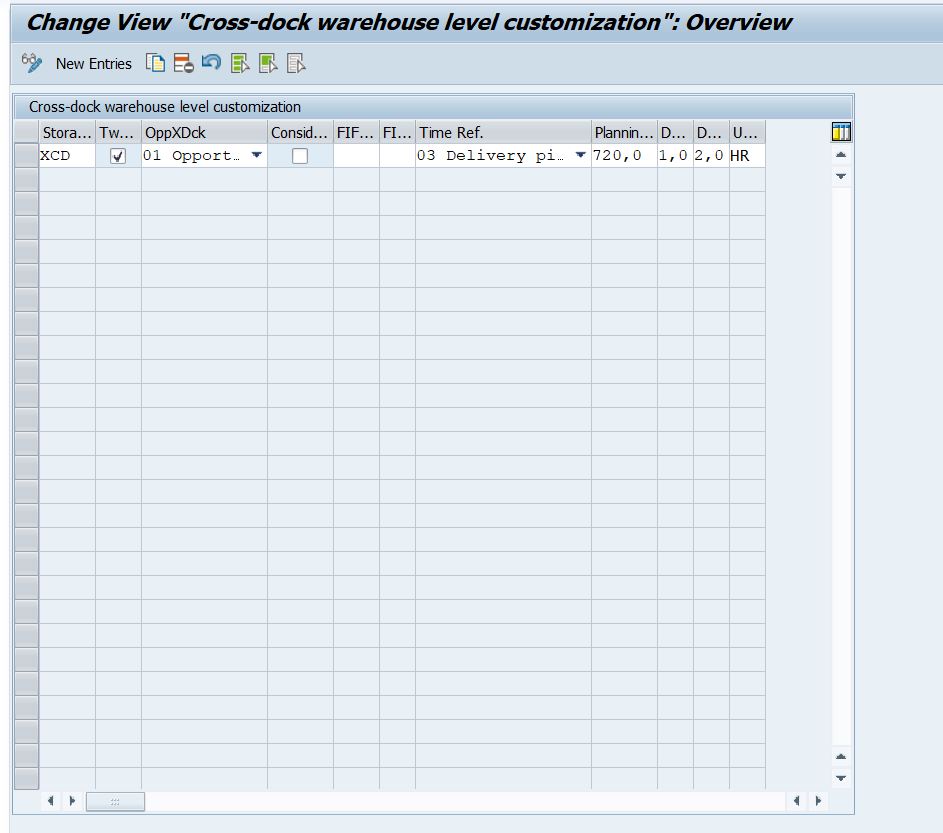

**Step 1**: Configure 2 Step Cross docking in SPRO at below path

SPRO -> Logistics Execution-> Warehouse Management -> Cross docking -> General settings-> Maintain Warehouse level settings

Select Two step checkbox and Choose 01 since we are activating planned CD process. In standard SAP system , storage type XCD is used for Cross Docking storage type for Two Step process.

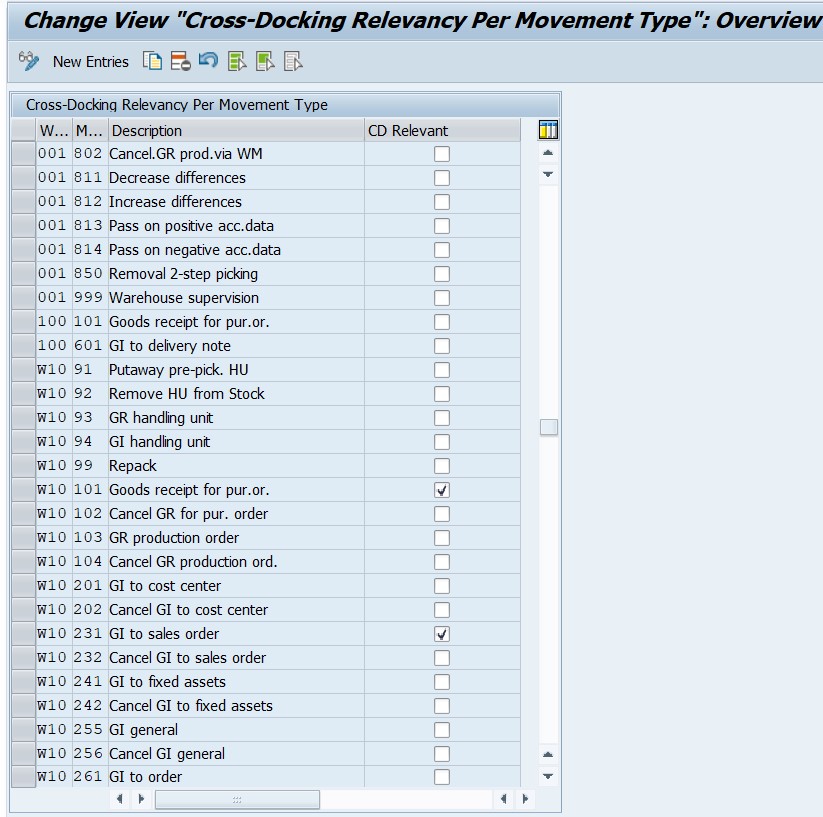

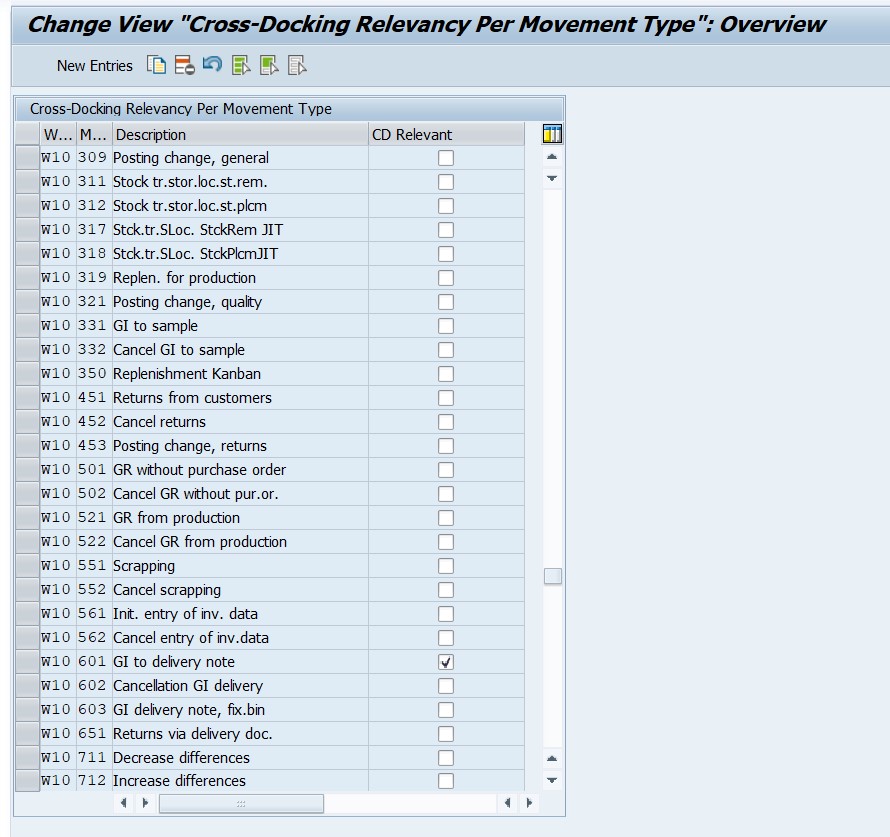

Step 2:** **Enable Cross Docking for Movement types Outbound Delivery and Inbound TR.

SPRO -> Logistics Execution-> Warehouse Management -> Cross docking -> General settings->Define Cross-Docking Relevancy for Movement Types

Select CD relevant checkbox for GR against PO (101) and GI for Sales order Movement types (601)

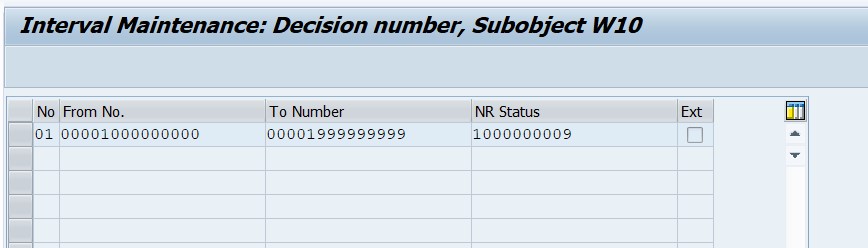

Step 3: Configure number ranges for Cross Docking Decision

SPRO -> Logistics Execution-> Warehouse Management -> Cross docking -> General settings-> Define Cross- Docking Decision Number Range

Scenario** for Planned Two Step Cross Docking – Foreground Process**

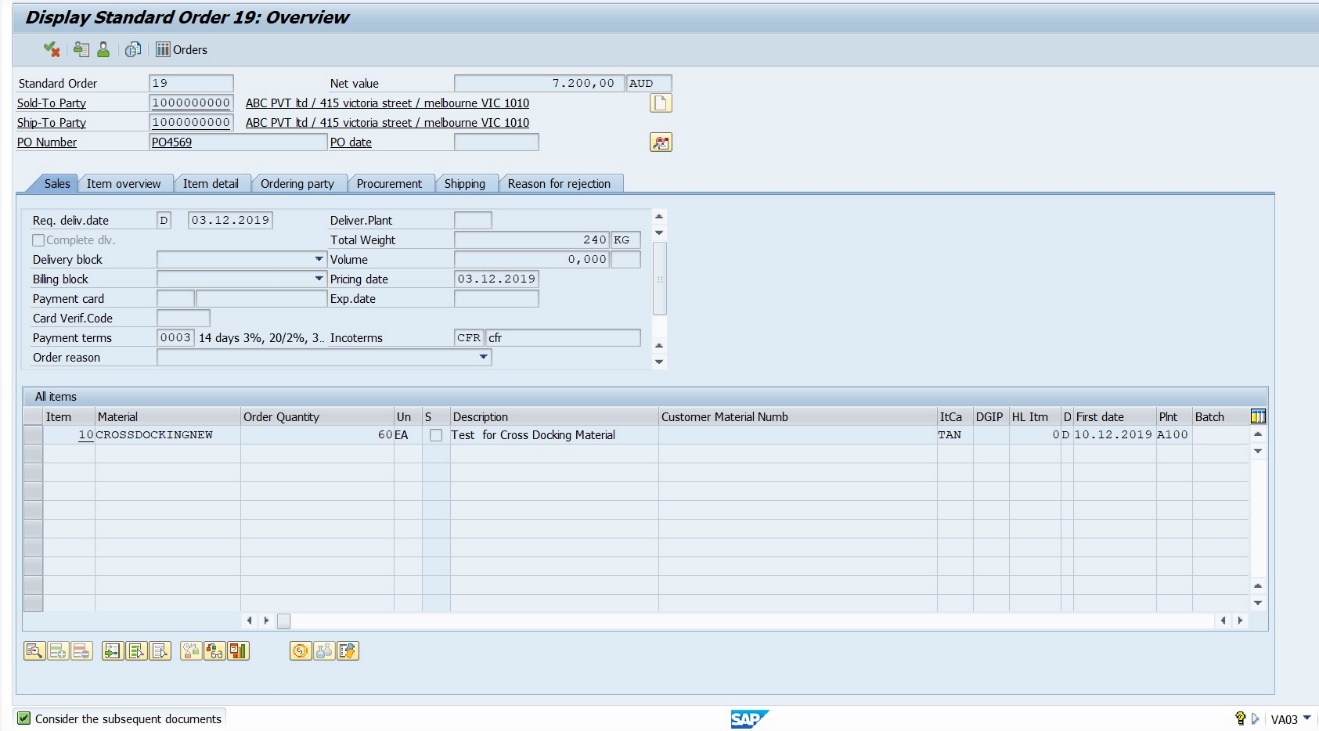

Step 1:** **Create Sales Order for Material For 60 quantities using T-Code VA01

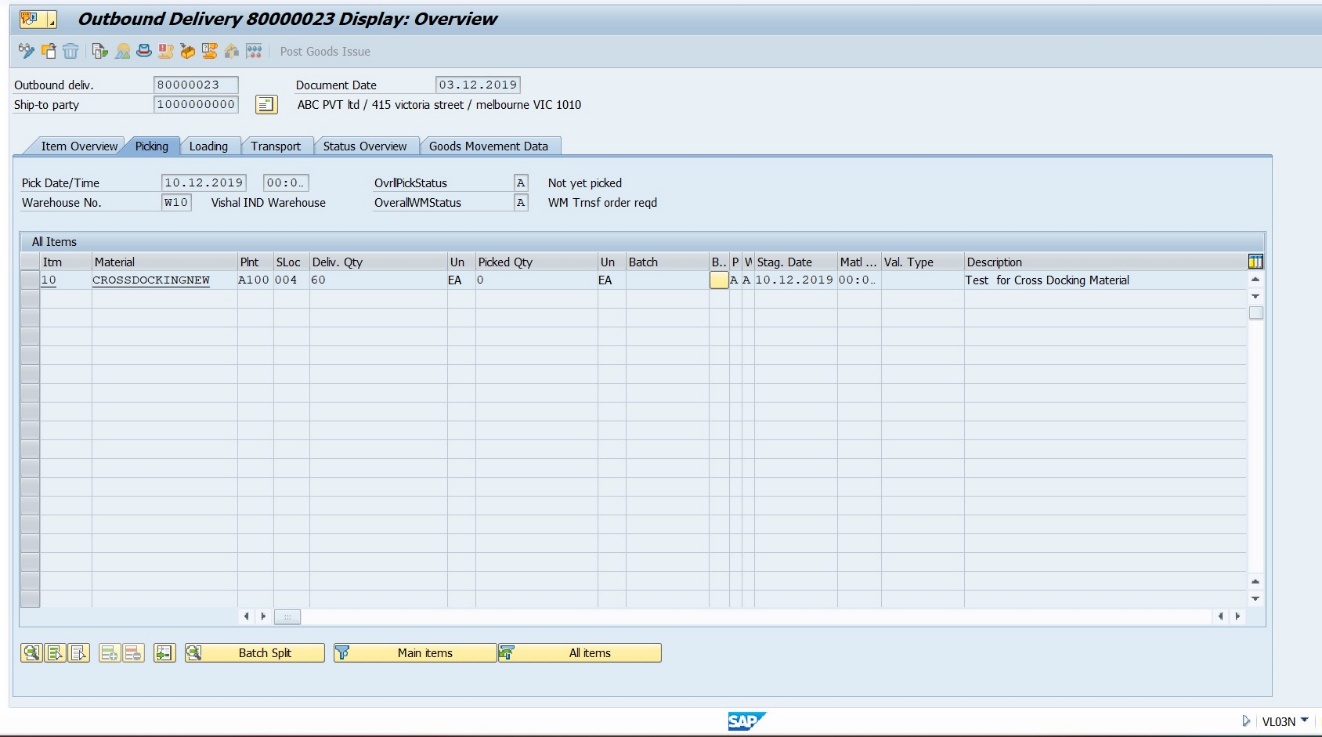

Step 2:** **Create Outbound Delivery in VL01N and save it.

Step 3:** **Create PO for same material for same quantity i.e. 60 using ME21n

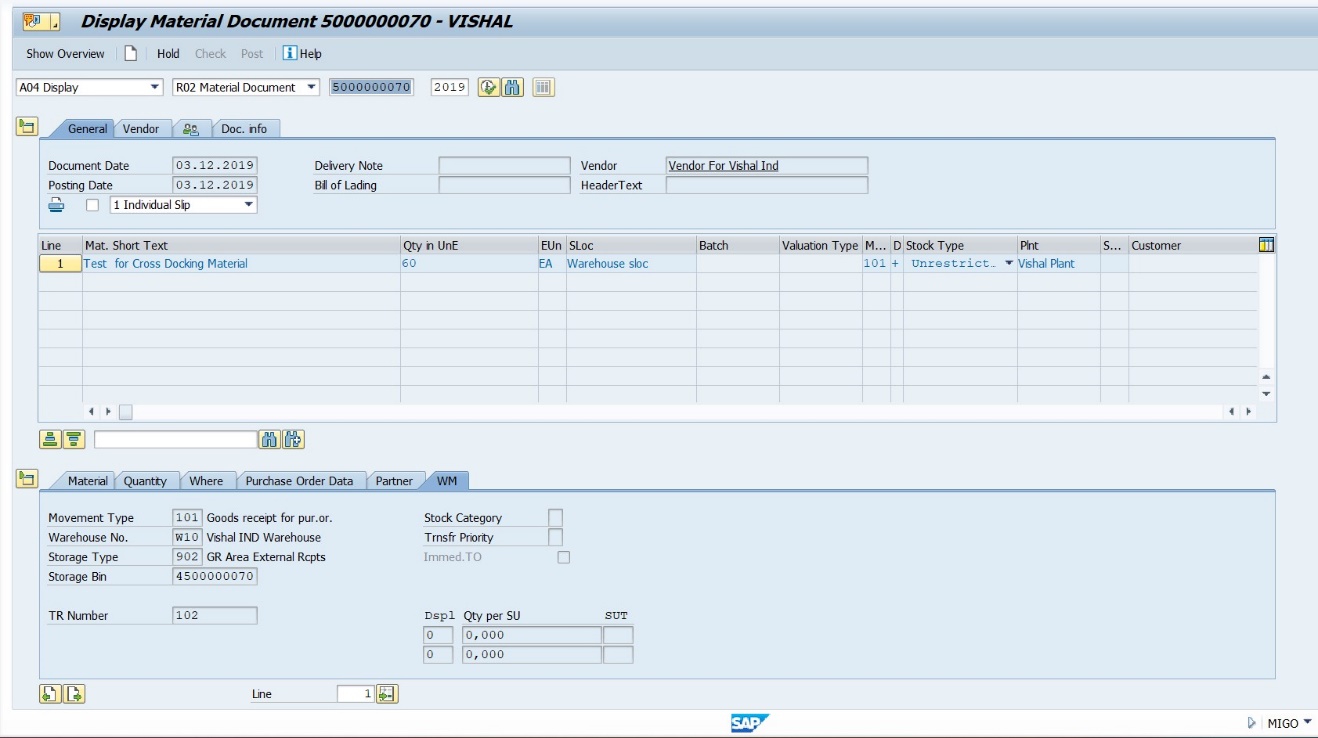

Step 4:** **Do the good receipt for this Purchase Order in T-Code MIGO

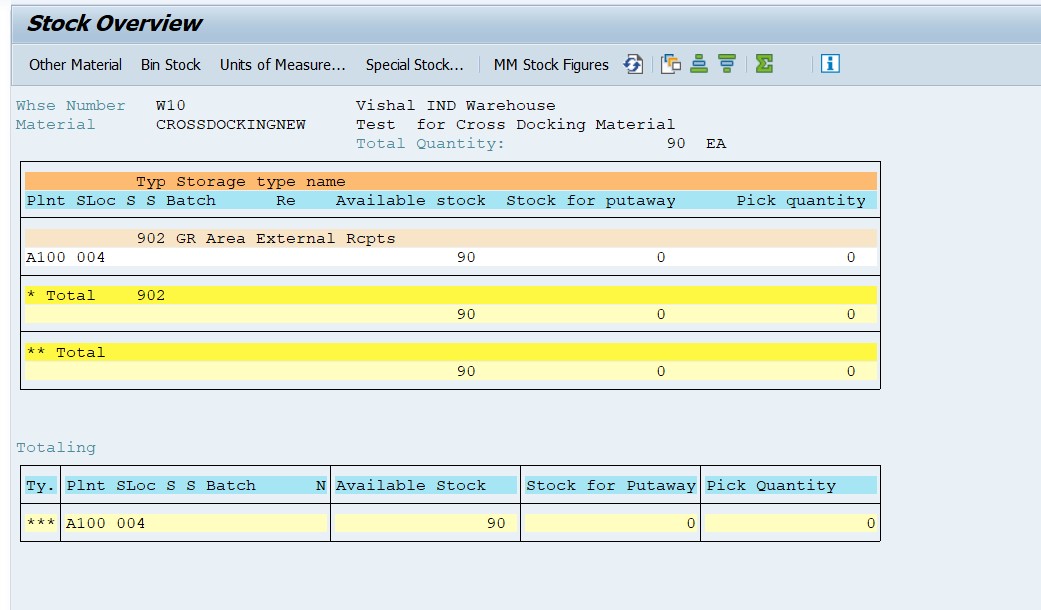

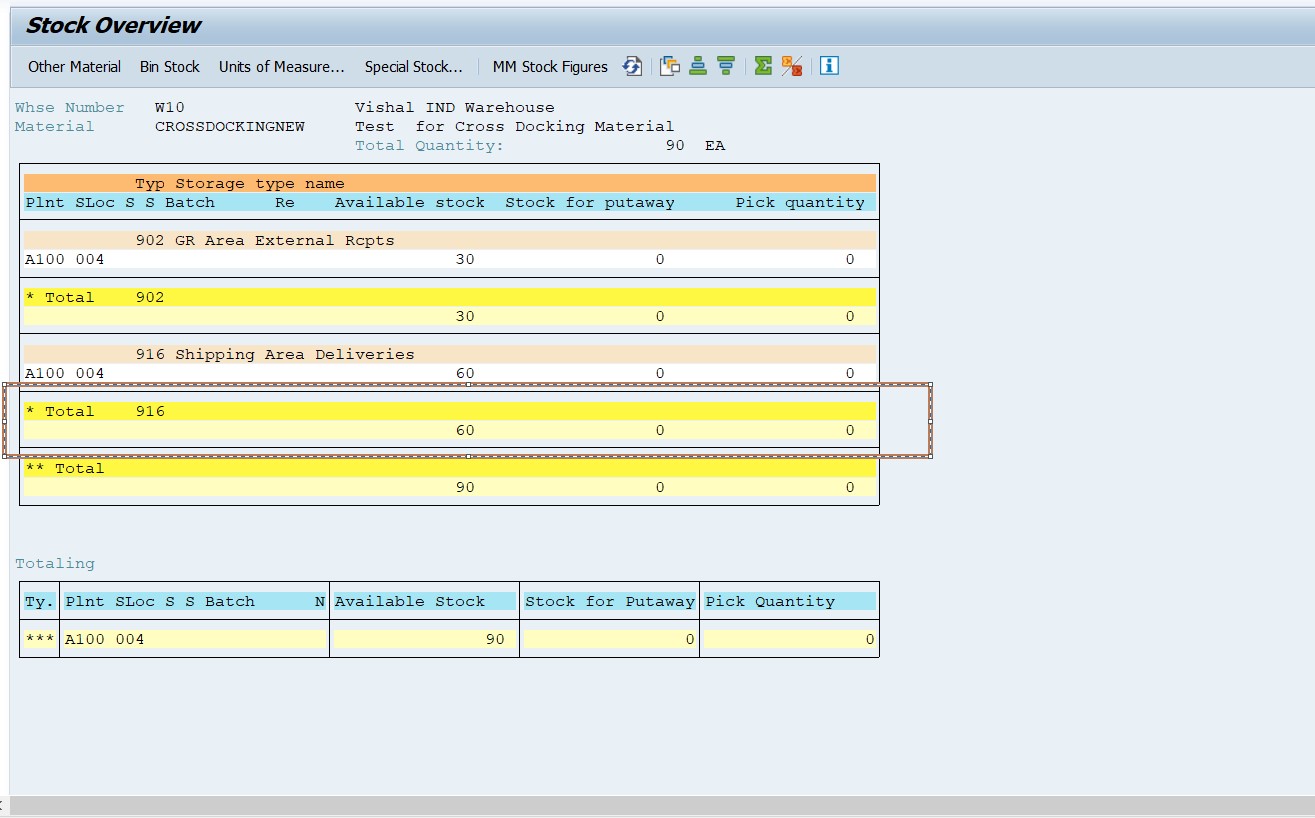

Step 5: Check stock for Material in WM

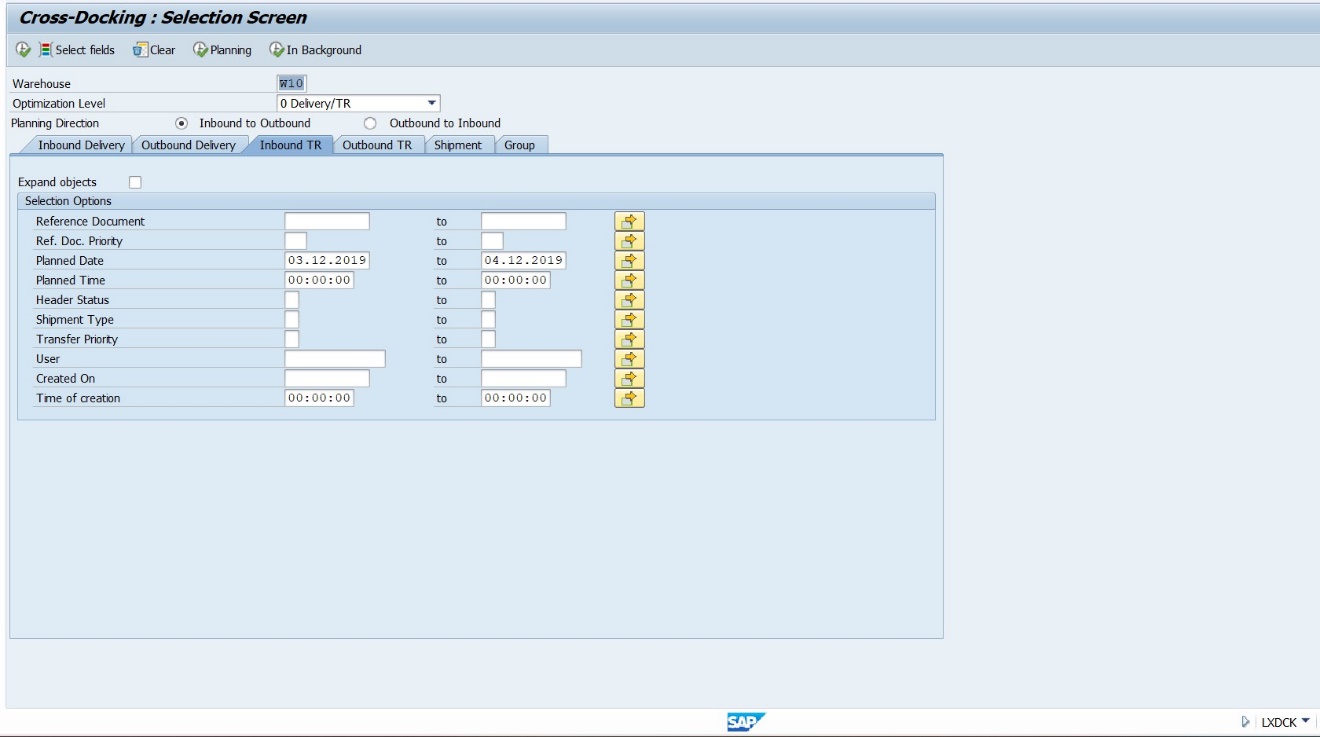

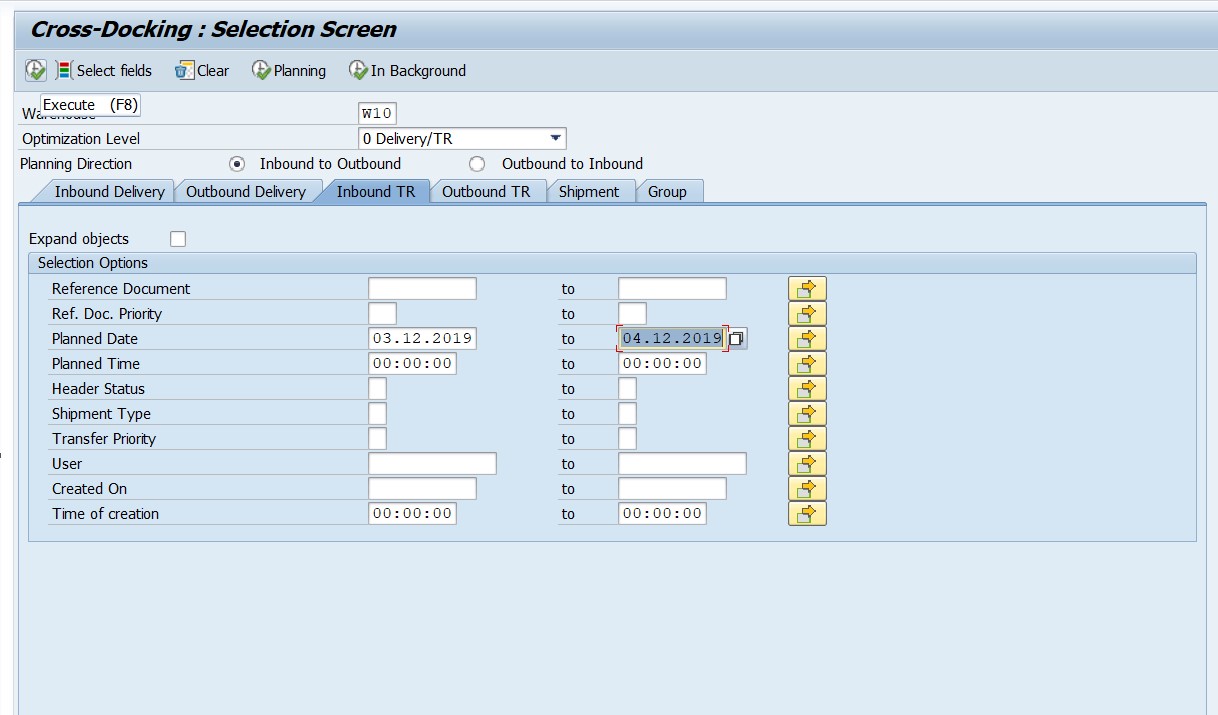

Step 6:** **Go to Cross Docking Monitor Screen using T-code LXDCK

Give 3 weeks range for outbound delivery as shown and 1-day range in Inbound TR

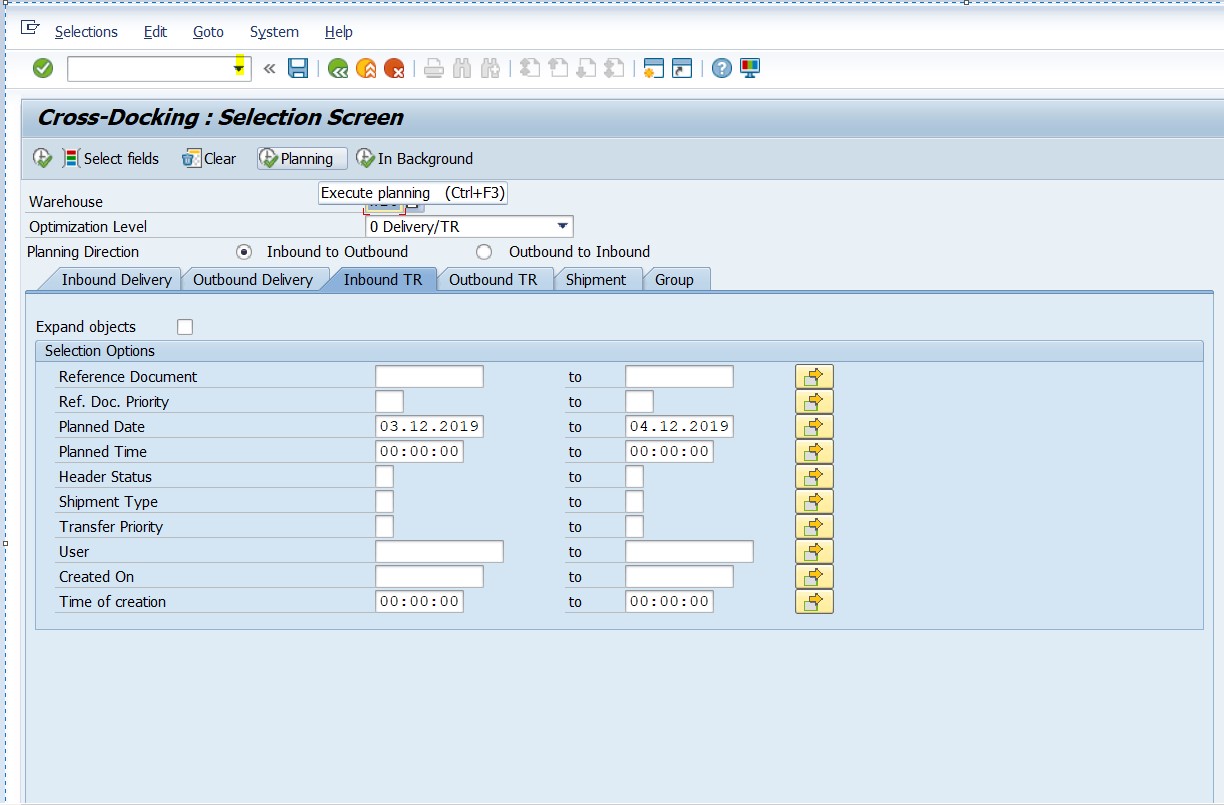

Step 7:** **Click on Planning button if you want to make decision in foreground or click background

If you want decision to be made in background.

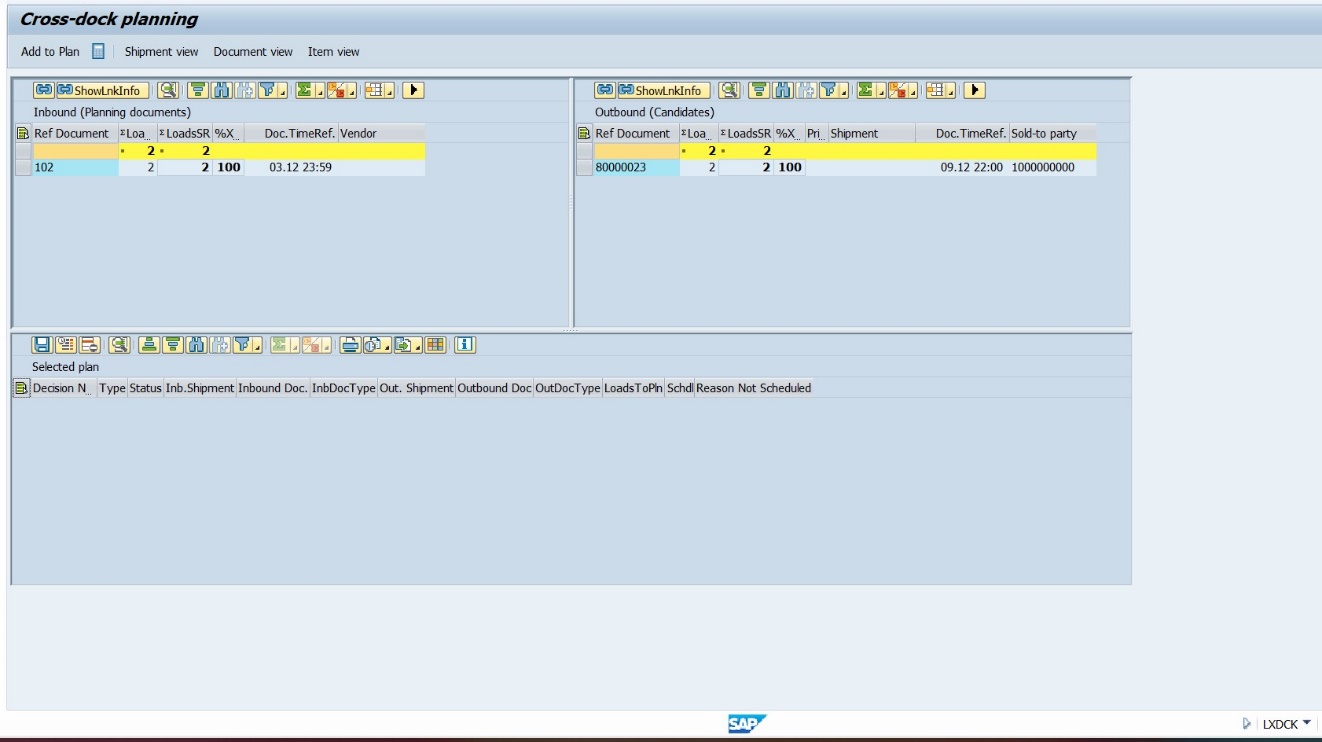

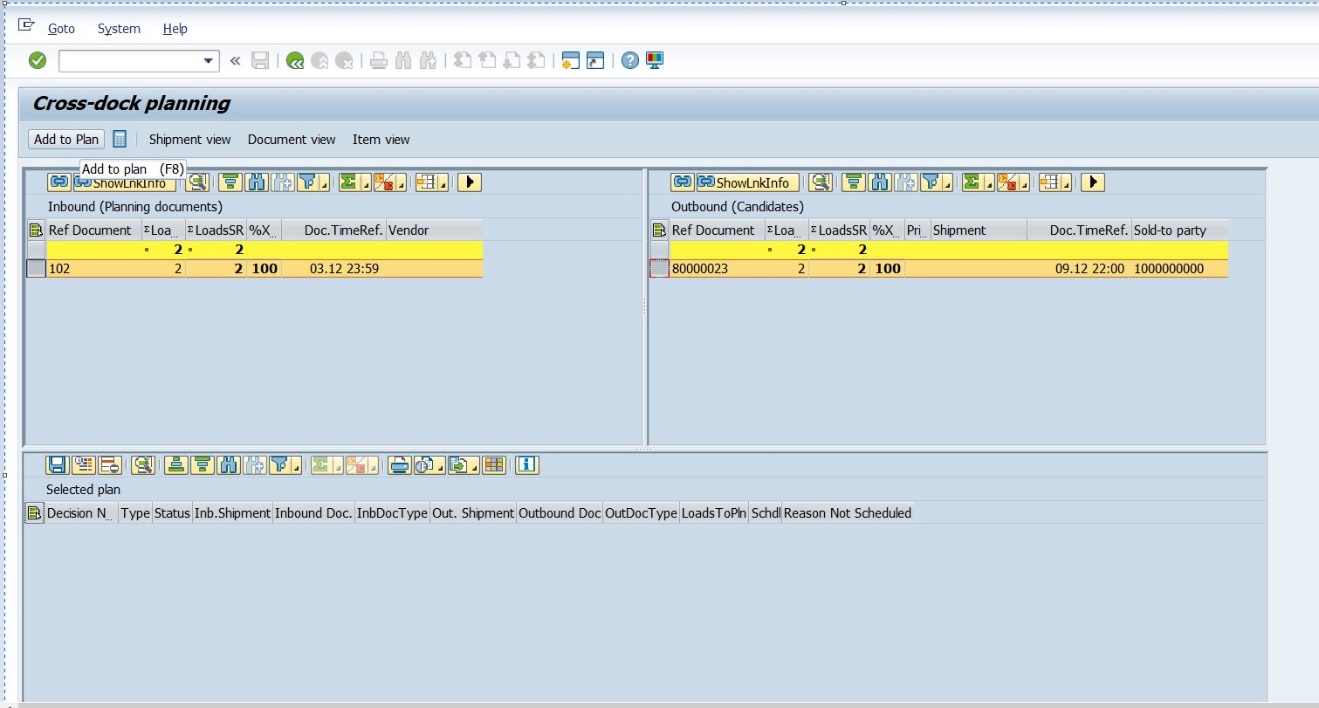

Step 8:** System will propose the Cross-Docking decision based on standard criteria as shown below.**

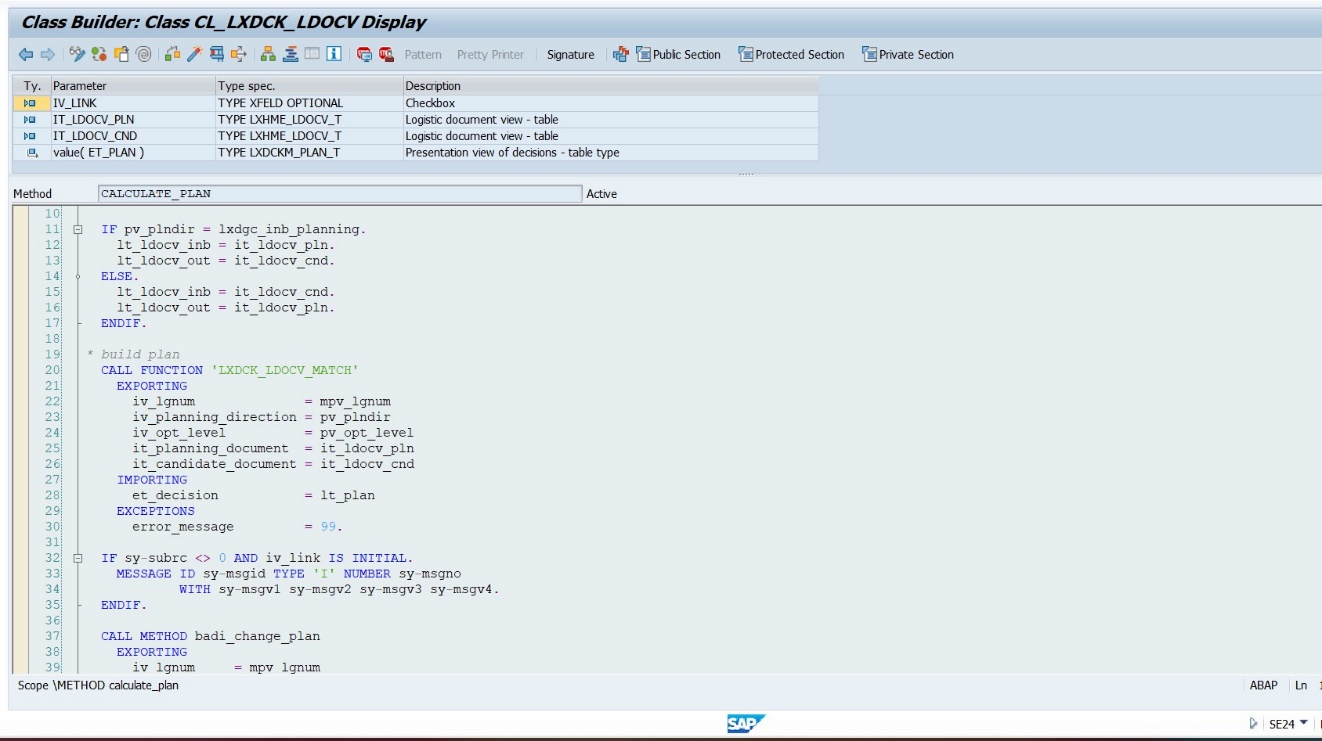

If you want to check match criteria Please check class CL_LXDCK_LDOCV. Method name is Calculate Plan. We can also implement BADI if customer has requirement which is not catered by standard.

Step 9:** **Select both of the Inbound and Outbound items and click Add to Plan and click on Save

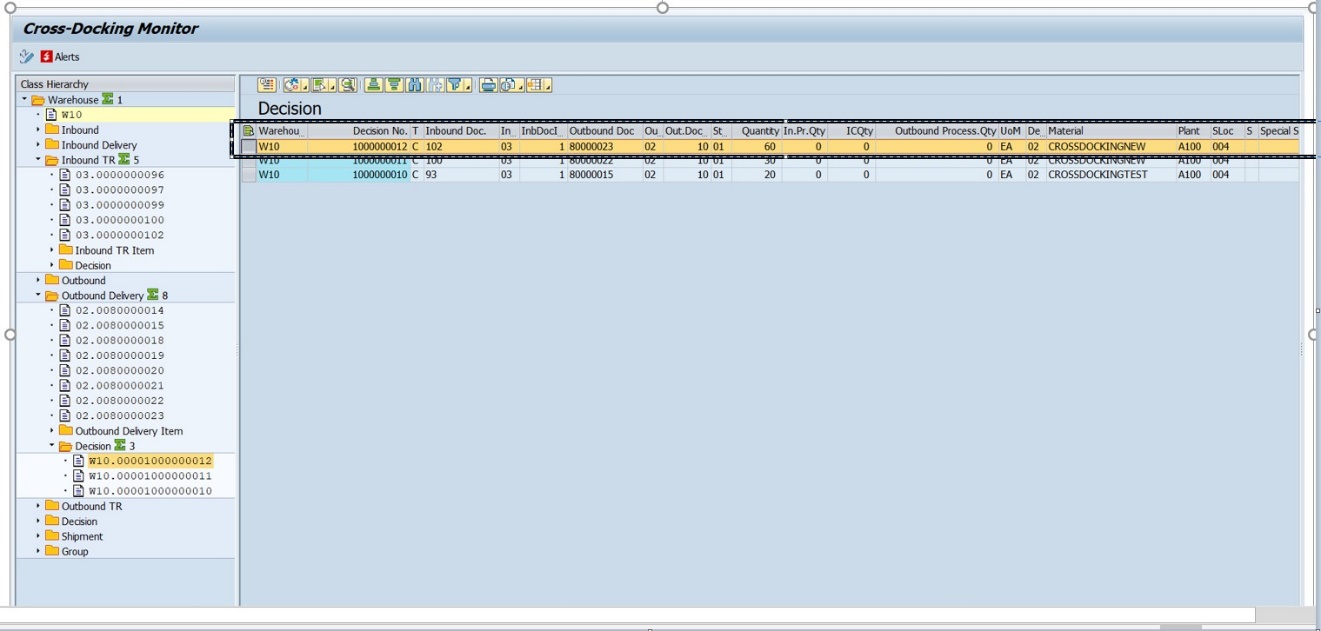

Step 10:** **Decision will be saved. Exit the screen and click Execute again, Decision can be seen on screen

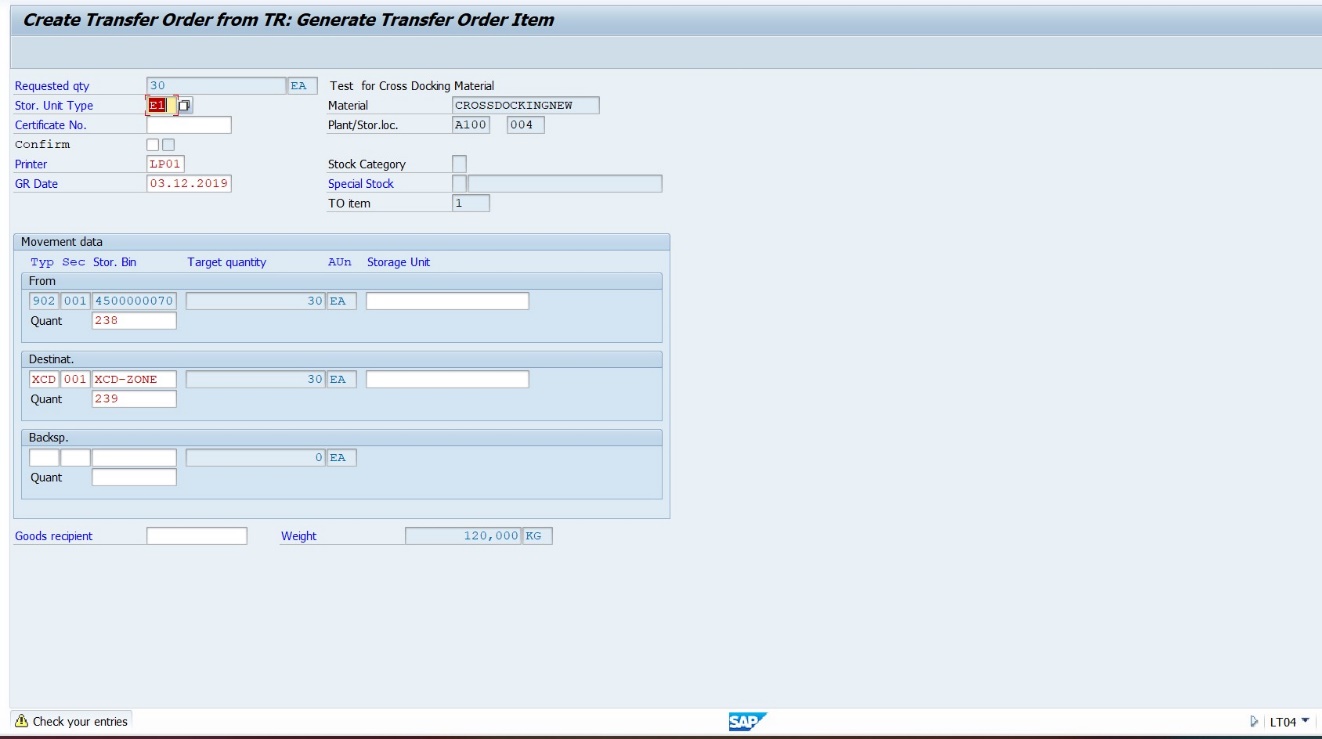

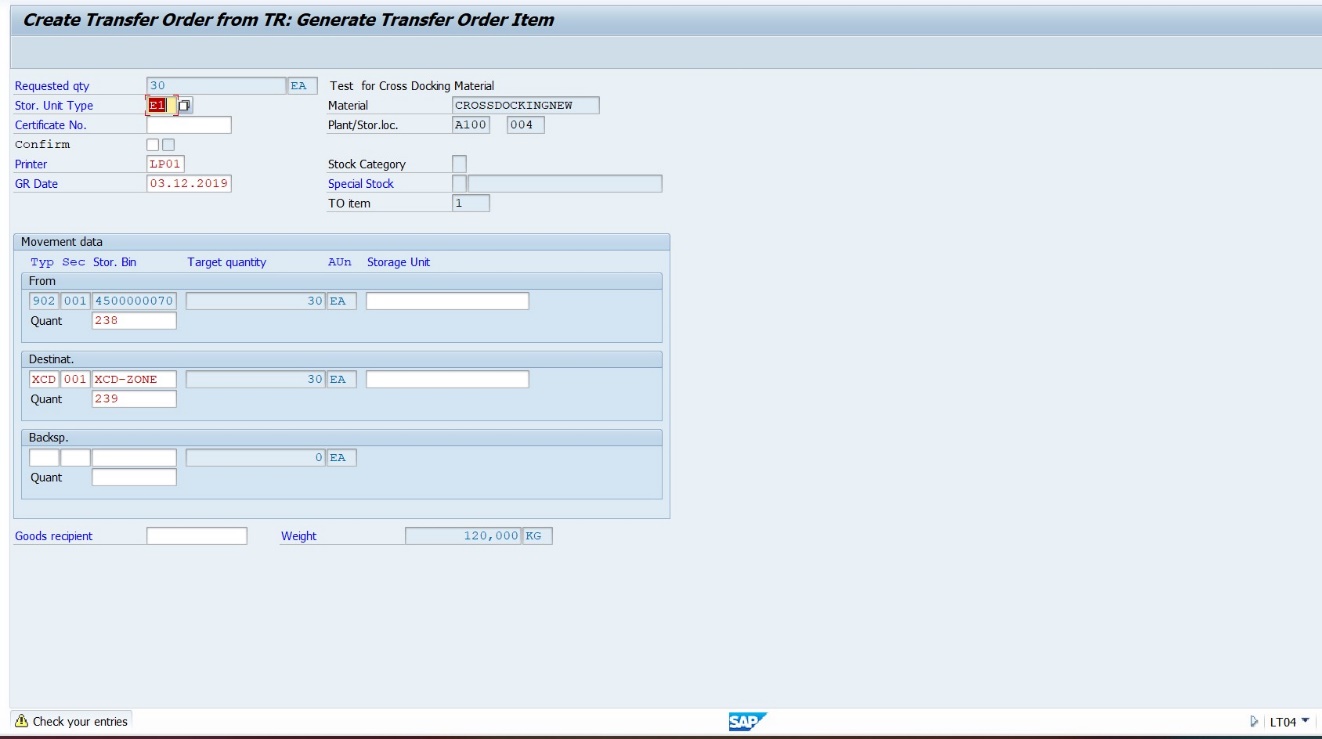

Step 11:** **Create TO for GR Document created in step 4 using T-Code LT04. Choose foreground and as we can see system proposes storage type XCD as configured in SPRO in Step 1 of Configuration steps.

Put away the 60 quantity to Cross Docking Storage Type.

Save Transfer Order

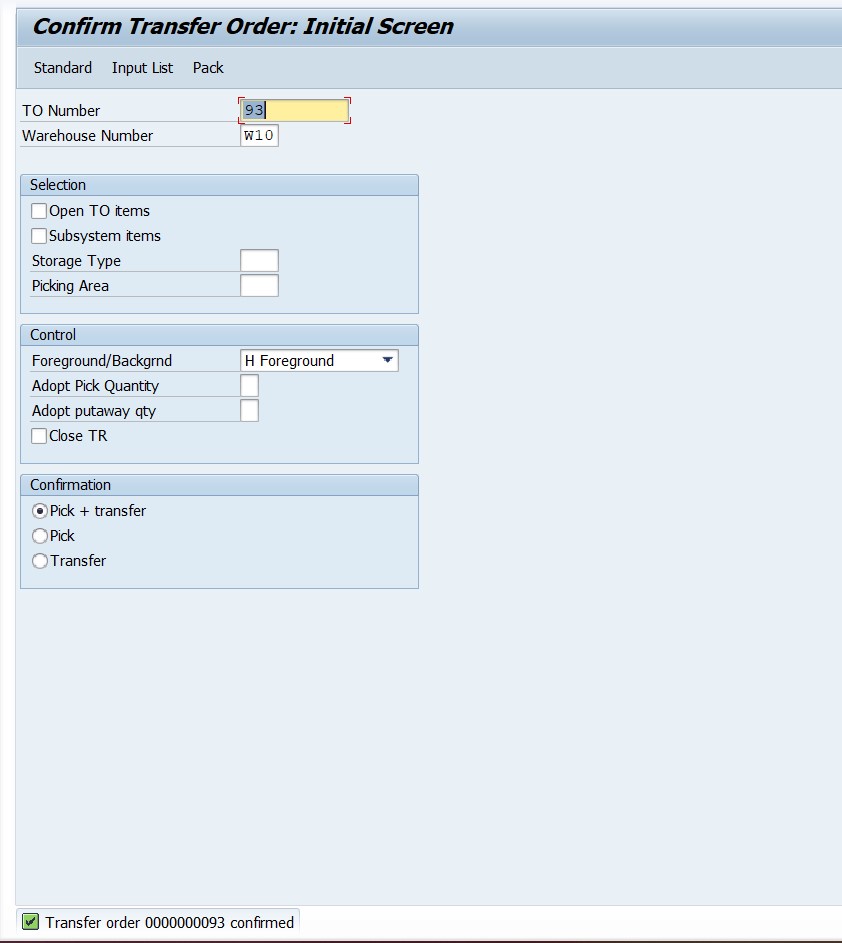

Step 12:** ** Confirm Transfer Order in T-code LT12

Step 13: Check Stock in LS26 and it shows 60 quantity has been put-away to Cross Docking

Zone.

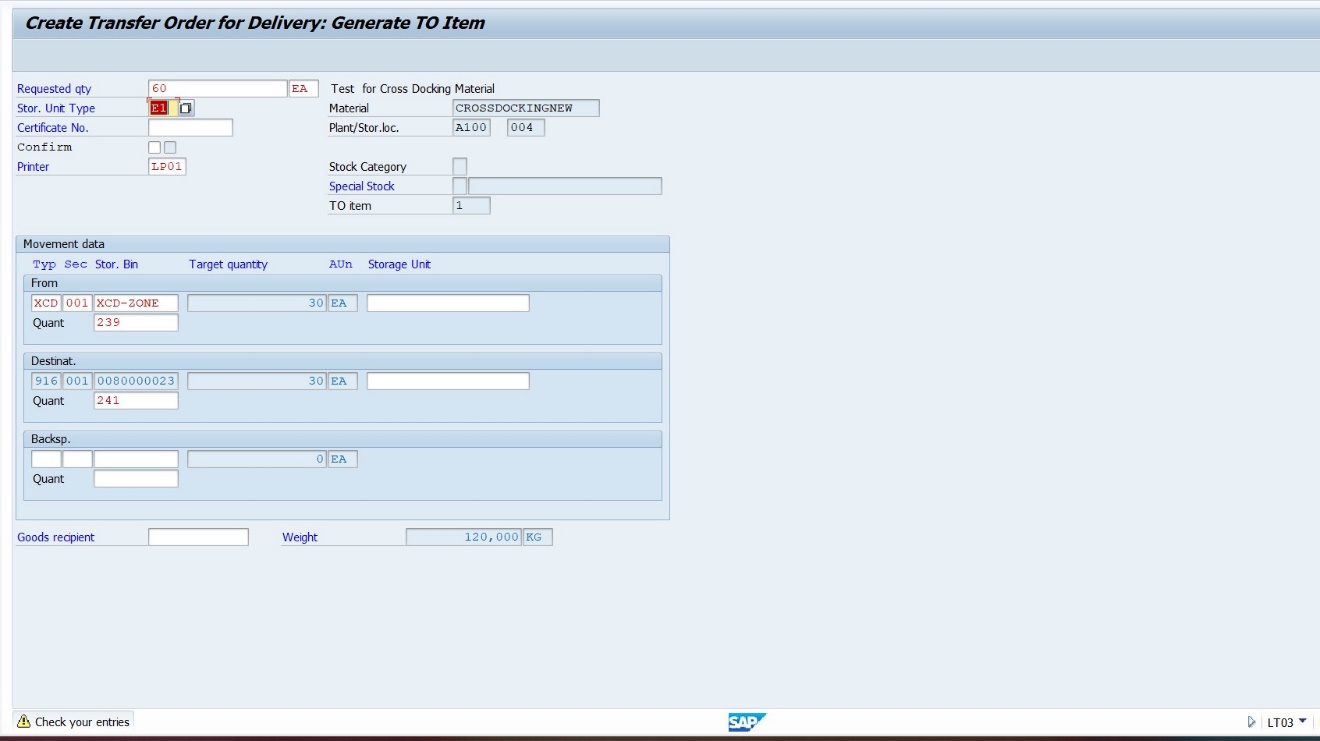

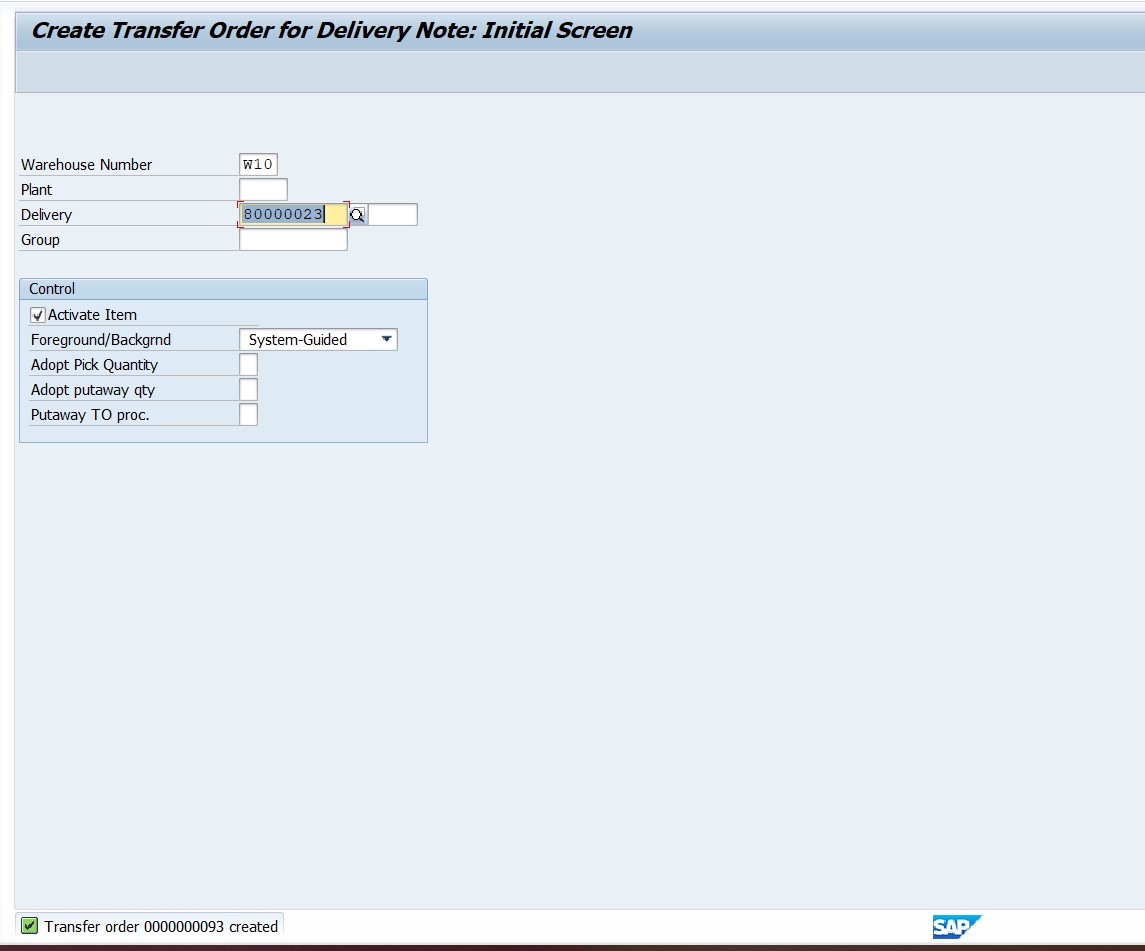

Step 14:** **Create TO for Outbound Delivery created in Step 2 if automatic or immediate TO is not configured in SPRO. Choose Stock Removal Foreground and see that system proposed removal from Cross Docking storage type

Step 15: Confirm TO in T-Code Lt12

Step 16: Check Stock of Material in WM .60 Quantity of Material has been moved to GI interim storage type 916

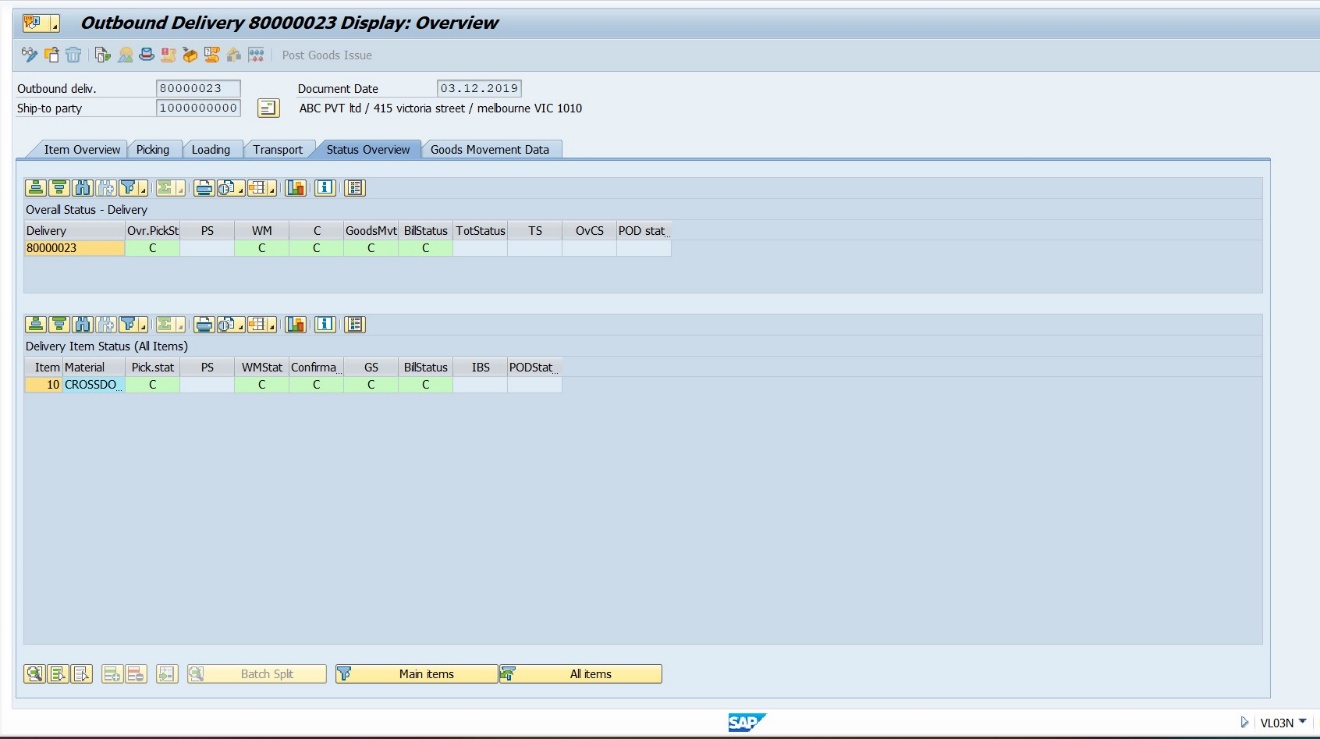

**Step 17:** Do PGI and check status of Delivery. It shows Status as C under WM and Good Movement.

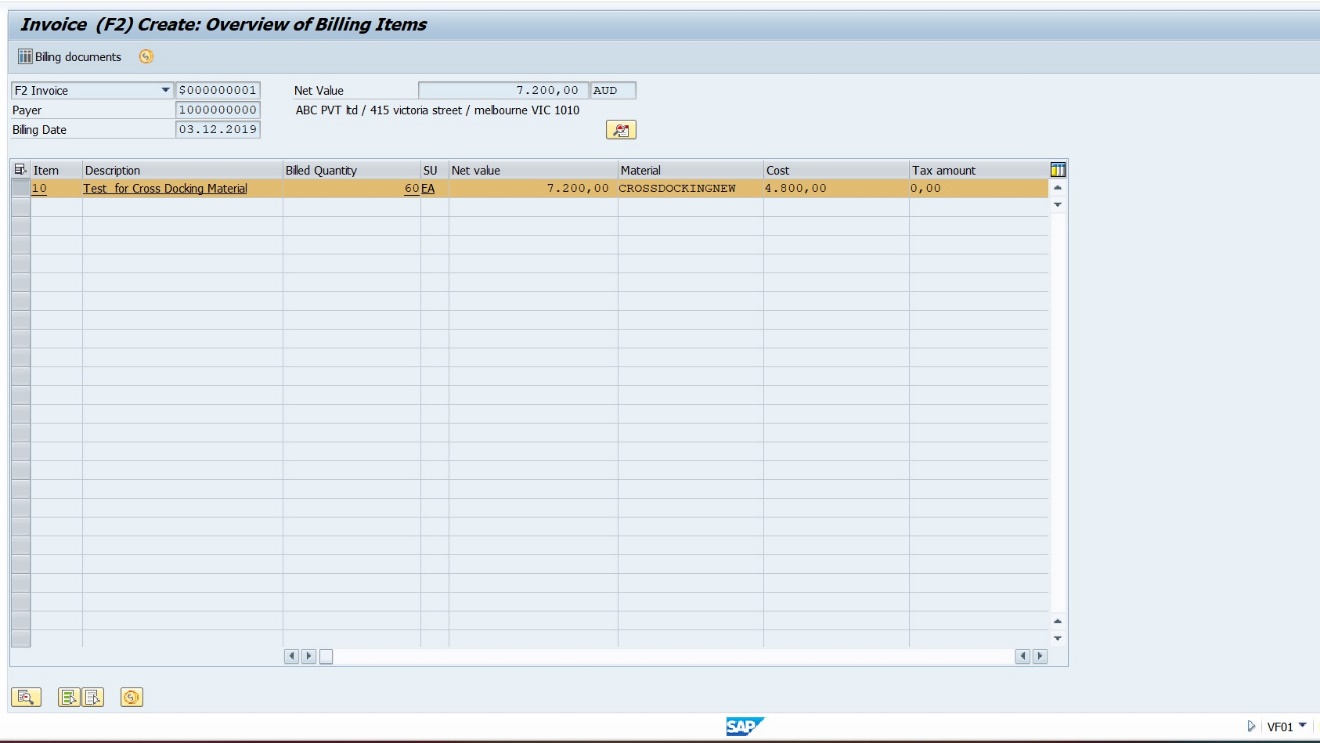

Step 18:** **Create Sales Order Billing document in VF01 T-Code ( Optional Step for WM)

Check Status of Delivery document now, it should show all Status as C

Conclusion :** **Applying Cross Docking in warehouse helps in cutting delivery time thus increases customer satisfaction and reducing operating costs since no material handling is required between Good Receipt and Good Issue process.

https://blogs.sap.com/2019/12/05/two-step-cross-docking-in-sap-warehouse-management/

还没有评论,来说两句吧...